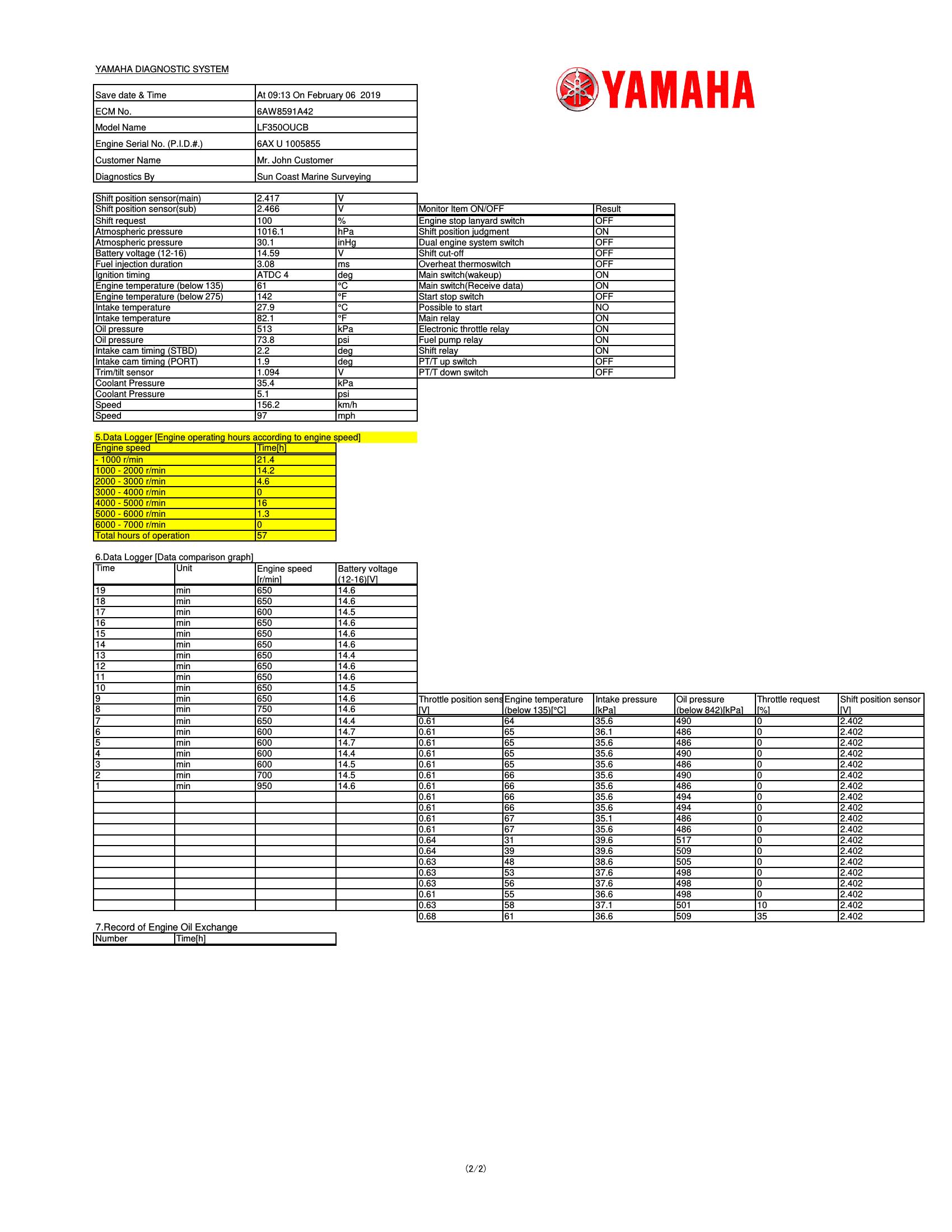

What is Marine Engine Diagnostics?

Marine Engine Diagnostics is a method of analyzing an engine by connecting the engine’s Electronic Control Module (ECM) to a computer system. The connection is done using an adapter that is unique to the engine. Communication between the ECM and the diagnostics software offers valuable information about the engine.

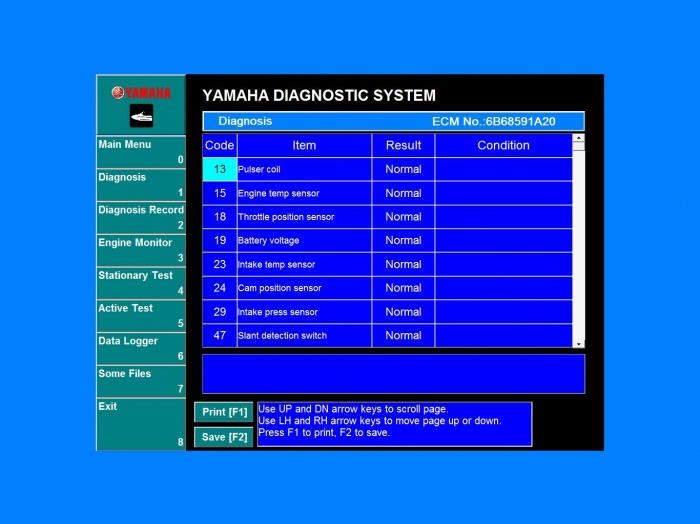

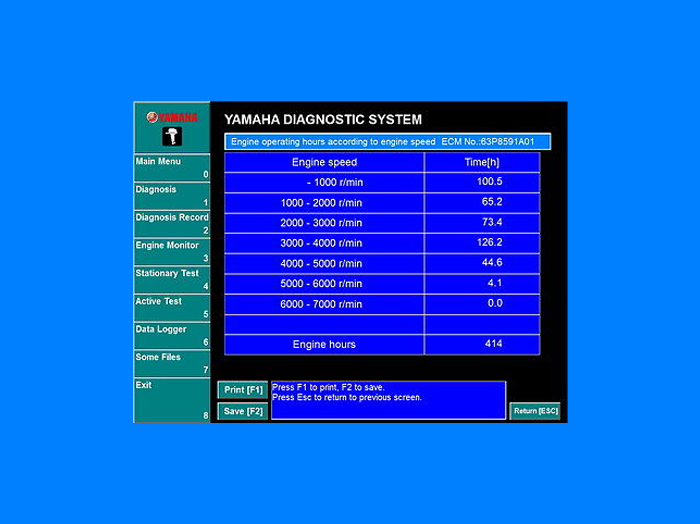

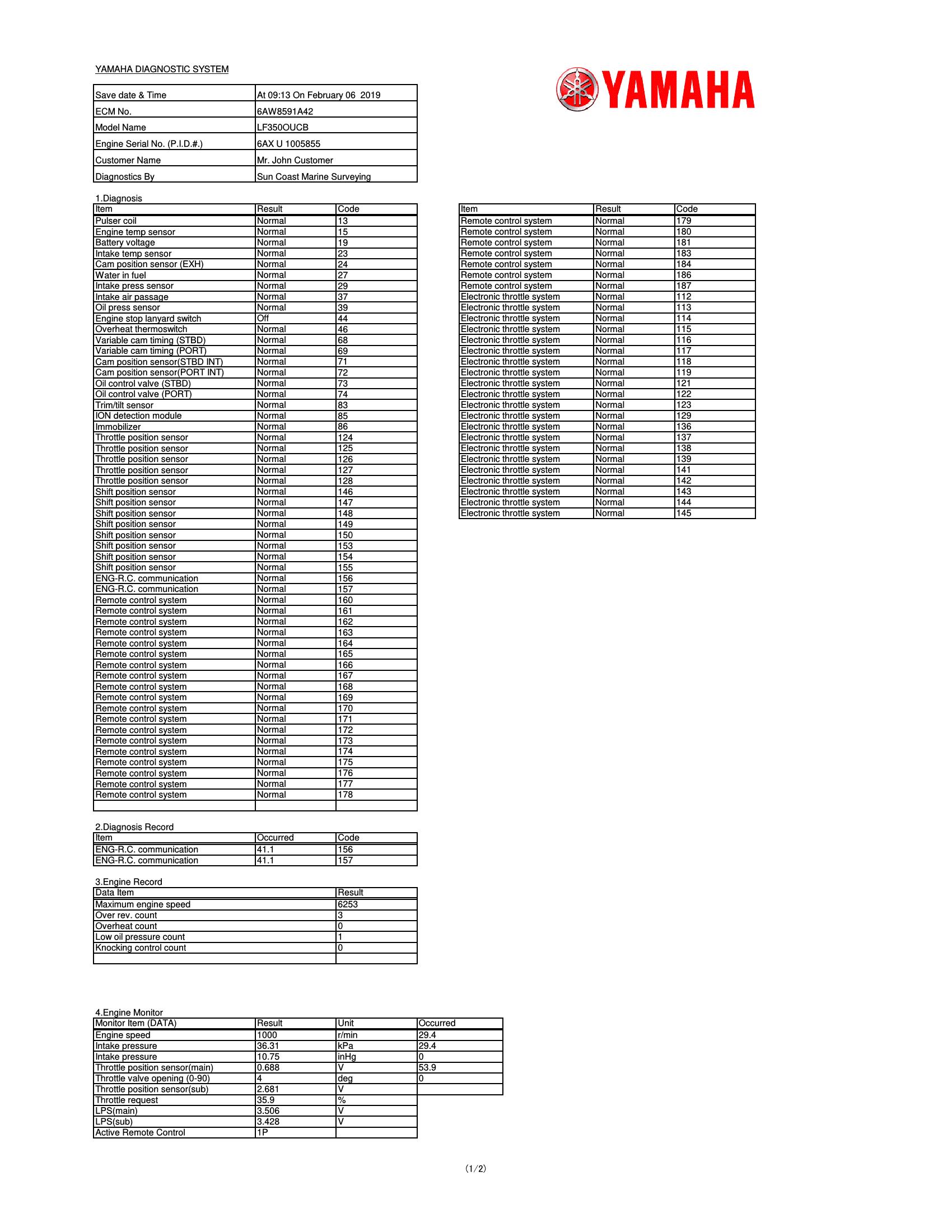

Marine surveyors connect to the ECM to collect such information as the actual engine hours, RPM runs history, current engine fault codes, historic fault codes and to simply understand how an engine has been used in its life. This information helps boat buyers make an informed decision.

When it comes to inboard-powered boats, our software is able to record the performance of the engine during sea trial. This makes it easy for surveyors to verify helm gauges’ accuracy and to collect accurate details regarding the performance of the engine during sea trial. While it is optional, you can request an engine diagnostic together with your marine survey. Our system works with all gasoline inboard and outboard engines provided they are ECM equipped.

.

Outboard Engine Diagnostics

At Sun Coast Marine Surveying we are happy to offer engine diagnostics on all engines including outboard and jet ski engines. Once it is connected to the engines ECM, our diagnostic software will help you verify the RPM run history of the engine, engine hours, service history and fault codes. This information enables buyers to know if they are making a good or bad investment when buying a boat.

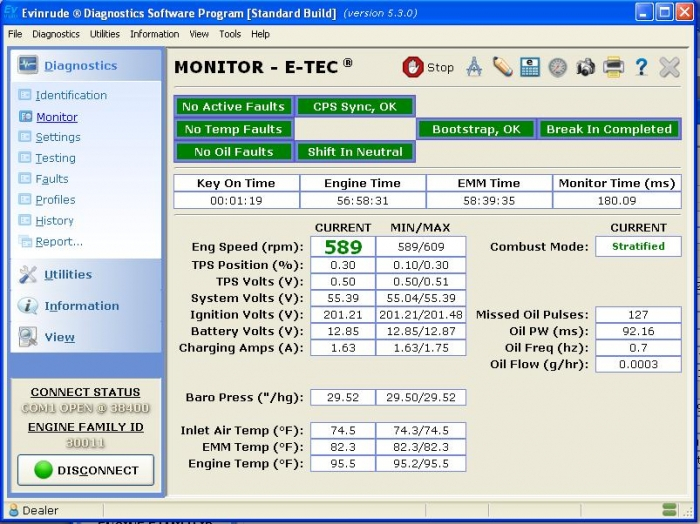

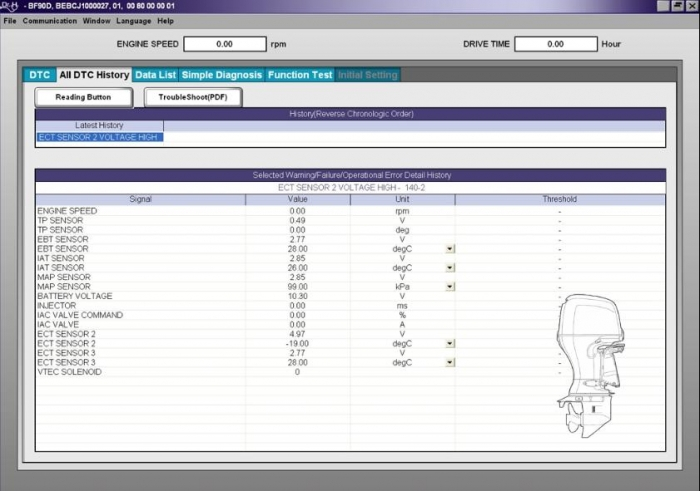

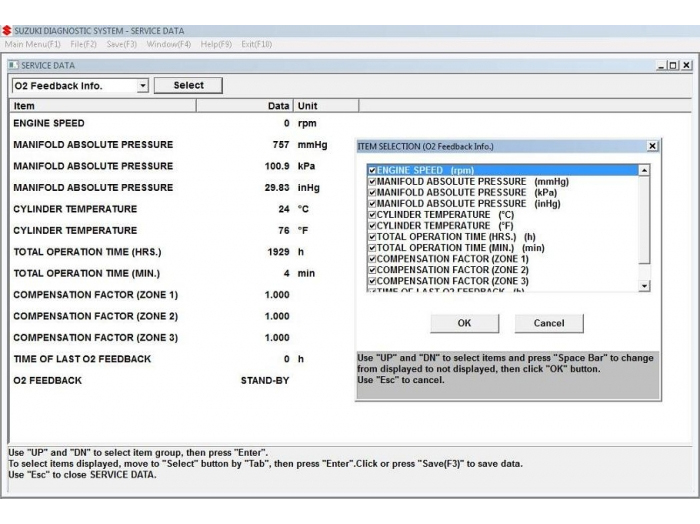

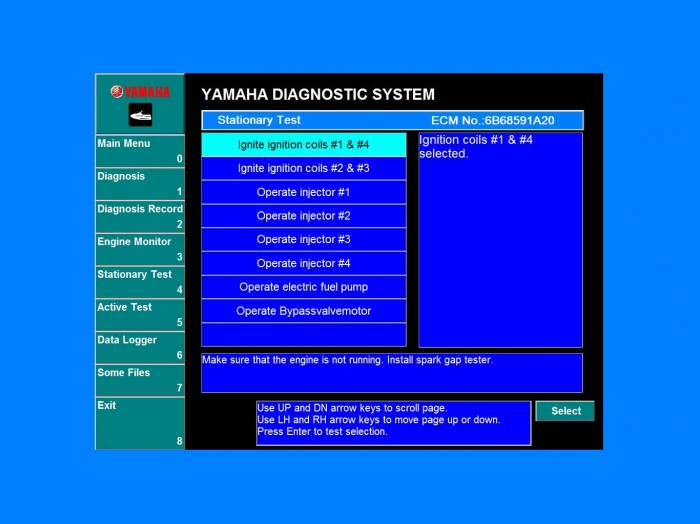

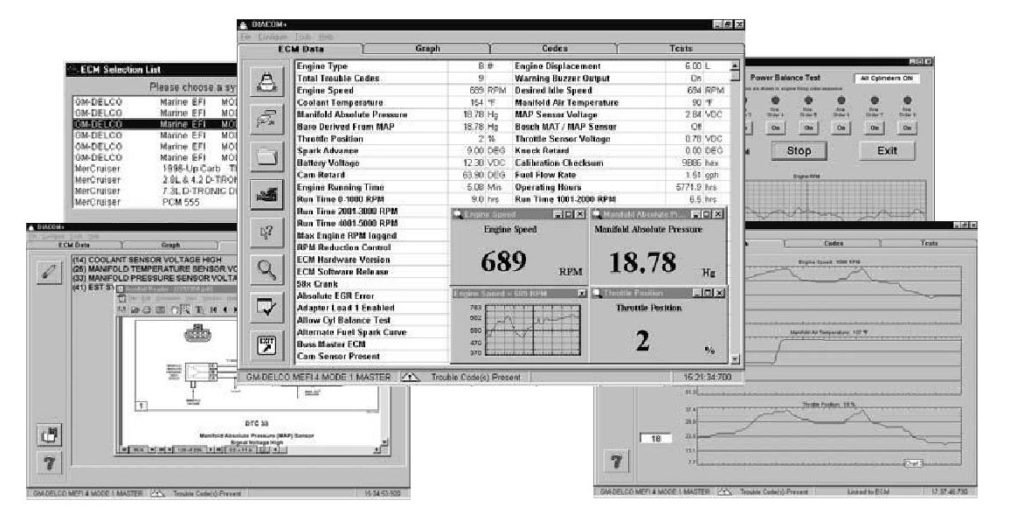

Outboard Engine Diagnostics Screen Shots

Diacom diagnostics tool supports MerCruiser, Mercury Outboards, Volvo Penta, lndmar, Pleasurecraft Marine, Crusader, Ilmor, Marine Power, Kodiak, Flagship Marine, GM RamJet Engines and more…

The Diacom diagnostic system is PC-based. It provides the power and flexibility of troubleshooting advanced marine EFI systems. The system supports the widest range of engines thus making it the most superior diagnostic tool for marine surveyors. You simply need a Windows-based netbook or notebook to harness the power of this intuitive diagnostic tool. It diagnoses EFI systems fast and accurately.

The Diacom diagnostic system is PC-based. It provides the power and flexibility of troubleshooting advanced marine EFI systems. The system supports the widest range of engines thus making it the most superior diagnostic tool for marine surveyors. You simply need a Windows-based netbook or notebook to harness the power of this intuitive diagnostic tool. It diagnoses EFI systems fast and accurately.

- Productivity means profitability.

Thanks to its rich features, the Diacom PC-based diagnostic tool helps you diagnose EFI faults within the shortest time - Remain compatible and competitive.

Diacom diagnostic system allows you to access CD-based service information easily, share the data over the Internet fast and free yourself from the hassle of dealing with multiple diagnostic tools.

.

PC Diagnostic Power

Diacom Marine diagnostic tool has taken marine engine service industry by storm. With modern engines having advanced control systems, it only makes sense to find a tool that allows you to pinpoint problems fast and accurately. Diacom diagnostic system offers that solution. It offers an impressive range of features that leave other diagnostic tools in its wake.

You Spoke, We Listened

We have managed to perfect our diagnostic tool because we always pay attention to what our target clients want. With Diacom Marine, we started as a blank screen. We then developed it from there using feedbacks and suggestions from marine service technicians. In the last decade, we have gained a lot of knowledge from marine service technicians and dealerships. This knowledge has enabled us to give our team of engineers an impressive wish list to think about. It is your input that has enabled us to come up with a diagnostic tool that is not only streamlined and discoverable but also intuitive. Diacom will help you get work done faster and hassle-free.

Internet Connectivity

Diacom is designed to make your work easier. That is why one of the things we have done is build it with the internet in mind. Our diagnostic tool will help you exchange engine data easily with other parties over the Internet. Diacom is also able to convert the collected engine data into formats that can be run on other programs such as Microsoft Excel and Access.

Big Screen, Huge Advantage

Computer screens are getting better. Diacom has taken advantage of this. We have created a user-interface that is not only intuitive but also with crisp images. Diacom user interface further takes advantage of the larger Notebook screens by making it easier for you to multitask. You will no longer have to keep hitting the scanner buttons, scrolling through lists of parameters or wasting time trying to remember what a certain EFI number means. The Diacom data display is customizable to make sure you are able to see every type of EFI system in a way that you appreciate. Added features like instant pop-up graphs, enlarged parameter windows, extensive data recording, side-by-side twin engine displays and report printing make Diacom the perfect choice for marine technicians.

Electronic Information Age

Engine manufacturers are now converting their technical bulletins and service manuals to digital formats. They are available in CDs and can be updated and searched easily. Diacom accesses these data efficiently and displays the relevant information effortlessly. You only need to click on the trouble code and the system will display relevant information.

Adaptable Tests

The EFI systems in the marine industry are ever-increasing. Tests created for a specific type of engine control system will not work for another system. This is why Diacom has adaptable ‘Tests’ screens that configure automatically for the EFI system you are investigating. Windows ActiveX programming technology helps display and deliver unique tests that apply to the specific system you are working on.

Special Functions

Factory-authorized dealerships know the importance of using the latest service technology. Our relationship with marine engine manufacturers enables us to incorporate specialized EFI systems in our Diacom Marin diagnostic tool. This means as a factory authorized service facility you can use a single integrated diagnostic program to troubleshoot, perform system upgrades and memory updates. ECM exchanges are minimized or even eliminated.

Factory-authorized dealerships know the importance of using the latest service technology. Our relationship with marine engine manufacturers enables us to incorporate specialized EFI systems in our Diacom Marin diagnostic tool. This means as a factory authorized service facility you can use a single integrated diagnostic program to troubleshoot, perform system upgrades and memory updates. ECM exchanges are minimized or even eliminated.

For More Information

To obtain a comprehensive list of features and information about Diacom Marine as well as other Rinda Technologies products, please visit our website at www.rinda.com. Product specialists can also be reached in the USA and Canada by calling 773-736-6633.

Diacom Kit Configurations

94010 – Diacom Marine: includes Diacom

CD, USB cable, #94005 MEFI and

#94006 PCM-555 adapters.

94030 – Diacom Marine + CAN: includes

Diacom CD, USB cable, #94005 MEFI

and #94006 PCM-555 and 94029 CAN

network adapters.

System requirements

To use Diacom, you need:

- Notebook or Netbook PC with 1 Ghz or higher processor.

- Microsoft Windows 7, Windows Windows Vista, Windows XP (both 32bit and 64bit versions of Win 7 / Vista are supported)

- 512 MB of RAM minimum

- 150 MB or greater of available hard disk space.

- CD-ROM drive

- USB port.

- SVGA (800 x 600) or higher resolution display screen.

- Mouse, touchpad, or compatible pointing device.

Additional items or services required to use certain features:

- Internet connection for email and web related features.

- Appropriate document viewing utilities such as Adobe Acrobat and Microsoft Internet Explorer to view electronic service information.

- Diacom special functions require usage authorization and data files supplied by engine manufacturers.

1. Engine service manuals in electronic format must be obtained from the engine and /or vehicle manufacturers.

2. Usage restrictions apply based upon dealer type and status. Diacom special functions vary with EFI system type and engine manufacturer.

Please note all specifications are subject to change without notice. Photos and screen images shown may differ based upon product version or other factors. Information presented in this document is believed to be accurate. Responsibility for errors, omisstbof inform ation or results from the use of this information cannot be assumed by Rinda Technologies, Inc.